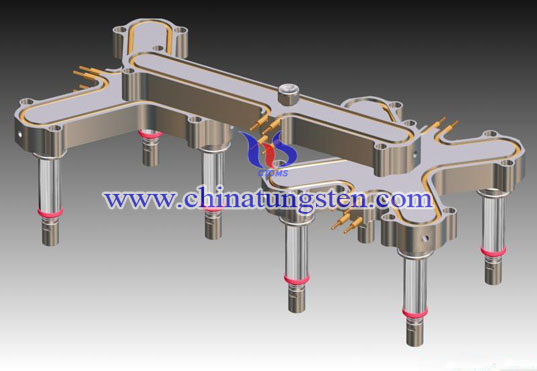

Open System TZM Hot Runner

Introduction

Hot runner is usually used in high-temperature environment, so often use good high temperature properties TZM alloy as a raw material for titanium zirconium molybdenum hot runner systems production. Hot runner system generally consists of nozzle, manifold, temperature controller and other components and accessories. Hot runner nozzles generally include two types: open system hot runner nozzle and valve system hot runner nozzle. Because the shape of nozzle directly determines mold selection and manufacturing, so often divided hot runner system into an open system TZM hot runner and valve system TZM hot runner.

Open system TZM hot runner structure is simple, suitable for miniature half hot runner, but not suitable for insulated hot runner. Mainly because insulated hot runner has high requirement on material, and direct contact with products surface, prone to leakage and drawing, having poor surface quality. Miniature hot half hot runner does not contacts with the product but contacts with the tiny runner, so usually use open system hot runner nozzle in high-precision molds. The advantages open system TZM hot runner is large plastic injection quantity, simple structure, and easy installation.

Importance of Hot Runner System

The melt delivery system is one of the most critical components, in developing a mold to produce an injection molded part. Hot runner (runnerless) systems are seeing more demand in today’s high-speed, high-volume molding operations due to higher material prices, a need to reduce cycle time, reduce scrap rates, and increase overall productivity and costs to manufacture, as compared to a “cold runner” system. At present, people recognize the importance of hot runners and we can offer high quality, high performance TZM alloy raw material for various shape hot runner and nozzle production. TZM hot runner is durable, dependable and has competitively priced so widely used in many field.