Molybdenum Knowledge

Introduction

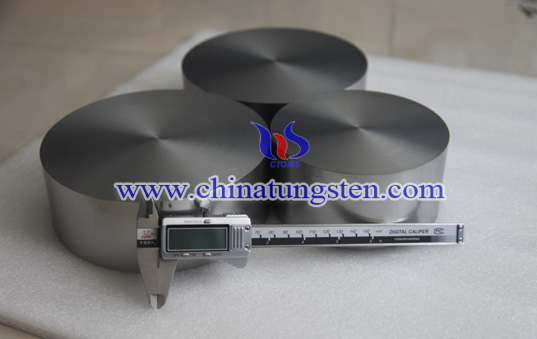

TZM alloy products have a variety of forms, including tube, block, plate, sheet, screw, nut, rod, bar, nozzle and other special shape. TZM alloy products have excellent performances have been widely used in industrial, military, aerospace and other fields.

TZM Alloy Properties

TZM alloy has many excellent properties including high melting point, high temperature, high strength, high elastic modulus, low linear expansion coefficient, low vapor pressure, good electrical and thermal conductivity, and good corrosion resistance and so on, so it is widely used in military, aviation, industry and other fields as high-temperature parts.

TZM Alloy Application

TZM alloy has many good properties, including excellent high temperature performance, mechanical properties and mechanical properties. So it is widely made as high temperature components, extensive mold, hot runner, valve body, rocket nozzles, gas pipelines, nozzle throat insert and other products used in aviation, industrial and military fields.

TZM Alloy and TIG Welding

TZM alloy has good weldability, so it is often welded into a variety of high temperature components used in various fields. Using TIG welding for TZM alloy welding can prevent oxidation and can effectively prevent oxygen and nitrogen intrusion during welding process, improving the properties of the alloy. Using TIG welding will weak the strength of the alloy, but it can improve the plastic toughness of alloy, maintaining sufficient strength to meet the requirements of ordinary high-temperature parts.

TZM Alloy Strengthening Mechanism

Strengthening mechanism in TZM alloy includes solid-solution strengthening, second phase strengthening and deformation strengthening. These three strengthening mechanical can improve TZM alloy’s properties. Compared with molybdenum alloy and other alloys, TZM alloy has greater advantage, thus expanding the using range and service life.

TZM Alloy Production Process

TZM alloy production commonly uses powder metallurgy method and vacuum arc melting method. The production processes are as follows: mixing - pressing – pre-sintering - sintering - several rolling and annealing -TZM alloy finished product.