TZM Hot Runner Systems

Introduction

Hot runner system is a combination, which includes nozzle, manifold, temperature controller, manifold and so on. Hot runner system as a common component of injection molding system uses electrical heating method to ensure plastic to remain molten. TZM alloy has good performance, so it is often used for hot runners and hot runner nozzles production and is widely used in hot runner systems. TZM hot runner system has good high temperature property, corrosion resistance and mechanical property, in terms of performance, service life and range of application has been greatly improved.

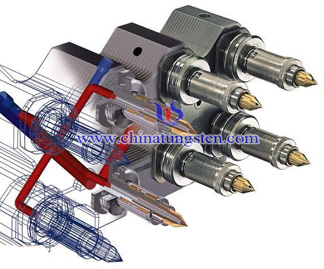

TZM Hot Runner System

Hot runner system usually consists of manifold, nozzles and temperature controller. TZM hot runner system having good high temperature performance, can long-term use at high temperatures. It is helps by precise temperature control method to send the molten plastic through sophisticated design of the manifold and a nozzle, dispensed into the mold cavity.

TZM Hot Runner Hot Sprue

TZM hot runner sprue is an important part of hot runner nozzle system and its main role is dispensed the molten plastic into the mold cavity.

TZM Hot Runner Nozzle

Hot runner system generally consists of nozzle, manifold, temperature controller and several components. TZM hot runner nozzle having high temperature resistance, high strength, corrosion resistance and other excellent properties, are widely used in all kinds of hot runner systems.According to the shape of the nozzle it can be divided into open type nozzles and valve type nozzle.

TZM Hot Runner Nozzle Tip

TZM hot runner nozzle tips have good high temperature performance, which can long-term use at high temperature environment. Depending on the shape of the nozzle tip, TZM hot runner can be divided into open system hot runner system and valve gate hot runner system.

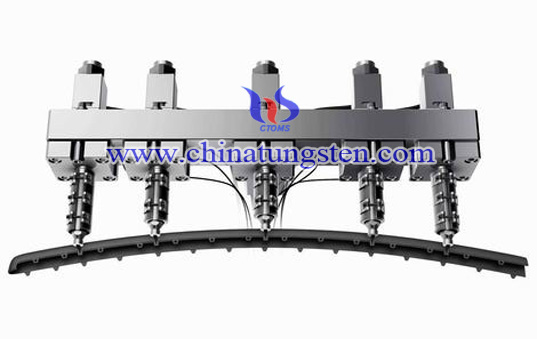

TZM Hot Half Hot Runner

TZM hot half hot runner has unique design, compared with other types hot runner it has good plastic flow, and it can reduce hot runner drawing, wear, leakage, gate blockage and other issues.

Hot Runner TZM Bar

TZM hot runner bar has good high temperature resistance and mechanical properties, and are often made of hot runner and nozzle used in hot runner systems.

Valve Gate TZM Hot Runner

Valve gate TZM hot runner has actuator can control the opening and closing movement of valve pin, so its structure is more complicated. Valve gate TZM hot runner turns off operation by valve pin mechanical operation, so it is not limited by plastic cooling time in the gate, witch can greatly shorten the production of plastic parts molding cycle.

Valve System TZM Hot Runner

Valve system TZM hot runner has processing program control, so it is beneficial for the injection molding process accurate adjustment, and commonly used in precision products, high quality products injection.

Open System TZM Hot Runner

Open system TZM hot runner has simple structure, commonly used in semi hot runner. Mainly because semi hot runner is not in direct contact with the product, but contact with micro hot runner, so there is no drawing and leakage phenomenon. Its biggest advantage is large plastic injection, simple structure, and easy installation.

Assembled Type TZM Hot Runner

Assembled type TZM hot runner’s all components are relying mold structure on-site assembly, to achieve structure transformation requires of special hot runner, to allows the manifold and the nozzle relative movement in the heating process, so it is applied to a larger thermal expansion angle hot runner system .

Integrated Type TZM Hot Runner

TZM hot runner according to the installation method can be divided into assembled type hot runner, integrated type hot runner and hot half hot runner. Integrated type TZM hot runner integrates hot runner's mechanical structure, electrical system, and hydraulic system as an integral, to avoid non-professional workers to touch the inside of hot runner system to greatly improve the safety of using.

Hot Half TZM Hot Runner

Hot half TZM hot runner includes hot runner backing plate, support plate and the code template. Its cavity can be individually removable, which is suitable for frequent disassembly mold using.

TZM Hot Runner Application

TZM hot runner system is kind of technology of plastic injection molding. It has widely application in auto, home appliances, electronics, medical and industrial applications.

TZM Hot Runner Injection Moulding

Hot runner injection molding is a molding method, it make plastic at high temperature to inject plastic into cavity, after cooled and solidified to obtain a molded product. TZM Hot runner injection molding having high efficiency, accuracy, and other advantages, are widely used in complex shape, large quantity plastic parts production.