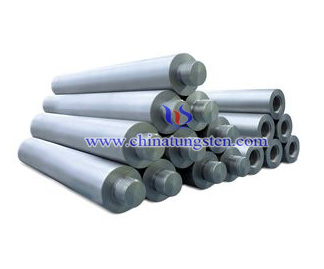

Molybdneum Melting Electrode

Introduction

Molybdenum having high melting point, good thermal and electrical conductivity, high strength and anti-corrosion and other good properties, is widely as electrode material melting for high-grade optical glass, fiber glass, rock wool and other fire-resistant manufacturing, so often referred to as molybdenum melting electrode. Molybdenum melting electrodes is often used in glass electric furnaces. In electric glass melting furnace, the electrodes are heated to produce thermal energy to melt glass at high temperatures. Glass electric furnace compared to the original glass furnace has many outstanding advantages, including high thermal efficiency, up to 80% to 85%, which can save a lot of energy. In addition, the molten glass produced by it has uniformity composition, high product quality. Production process tends to automate. Therefore, glass electric furnace has spread rapidly.

Molybdenum Electrode Quality Requirements

Molybdenum melting electrode density level and uniformity are important factors affecting the quality of the glass, to produce excellent performance glass molybdenum electrodes should have a certain quality requirements, such as high density, uniform density, small impurity content, high strength and resistance oxidation and so on.

To obtain good performance molybdenum electrode should strict control and improve electrode production process to improve product quality and performance. At the same time, doping a small amount of a rare earth element can change molybdenum grain size and performance, such as doping ZrO2 to produce new type molybdenum-based alloys. This new molybdenum electrode not only retains the original properties of molybdenum and significant increase in high temperature strength and corrosion resistance. Molybdenum electrode is easily oxidized at high temperature, so that the molybdenum electrode consumption rapidly and will decrease the service life. Besides, oxidized molybdenum electrodes are susceptible to corrosion by molten glass, causing the surface grain of molybdenum electrode peeling and loss. In order to prevent the molybdenum electrode oxidized at a high temperature, manufacturers can cover a oxidation resistant coating on the electrode surface.