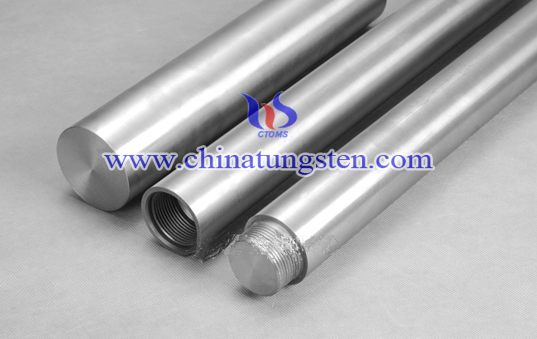

Molybdenum Electrode Used for Industrial Glass Manufacturing

Introduction

Molybdenum electrodes have good high temperature performance and have strong corrosion resistance in the molten glass. Besides, the product produced by molybdenum and molten glass is colorless and will affect glass products. So molybdenum electrode often in place of expensive platinum electrode used in glass furnace for industrial glass manufacturing. China's domestic flat glass production all uses molybdenum electrodes as the sub-heater, in order to improve the quality of the glass, to increase production. Also some factories of container glass, lamp glass, float glass, and thermos production also use molybdenum glass melting electrodes as a heater. Most glass furnaces usually use glass melting crucible with molybdenum electrode to melt glass, which can not only improve glass quality, and extend the life of the glass furnace.

Molybdenum Electrode Requirements on Industrial Glass Production:

1. Density should higher than 9.8g / cm2; 2. The electrode surface is smooth, dense, no pitting or pits; 3. Electrode hardness is about HRA50, easy machining; 4. The electrode can long-term work in 1300 ℃ molten glass and has long service life; 5. Under heating working condition it will not smoke.

To make molybdenum electrodes have the above requirements, the manufacturers should to improve the performance of the electrode during production process. Firstly, during pressing should use isostatic pressing, which can obtain density uniform distribution molybdenum blank. Using HIP can obtain molybdenum blank density at 7.0 g/cm3. In order to obtain smooth and densification surface should process rolling process on electrodes. The electrode processes multi-roll on the rolling machine, the surface defects has been eliminated. If to process finish rolling, the densification and smoothness of surface can be improved sufficiently and can greatly improve the surface properties of the electrode. Molybdenum electrode is easily oxidized at high temperatures, and thus at high temperatures will produce yellow smoke, which is MoO3. In order to improve the shortcomings of easily oxidized can add a layer of oxidation resistant coating on electrode surface, and common anti-oxidation coating is MoSi2 coating .