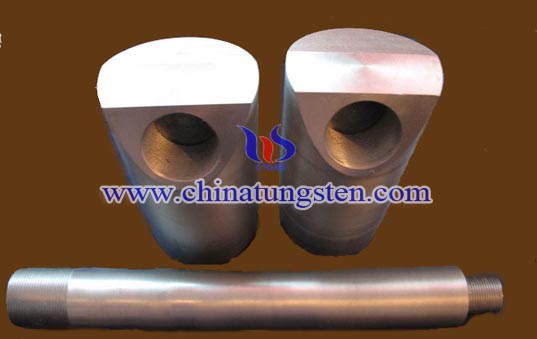

Molybdenum Electrode Used in Glass Furnace

Introduction

Molybdenum electrode has high temperature property and strong surface current density, commonly used in glass furnace, for soda lime glass and high boron glass production. In the glass furnace, the correct application of molybdenum electrode has certain significance for prolonging glass furnace and electrode’s service life, so to produce high performance molybdenum electrode is not only good for glass production, but also good for furnace and electrode. In general, the surface temperature of the molybdenum electrode is higher than the melting temperature of melting glass, and is generally higher 200 ℃. If the molybdenum electrode surface temperature exceeds 2000℃, the electrode loss will be larger. In addition, molybdenum electrodes surface temperature is connected with surface current density, so the higher the temperature, and the greater the surface current density, so the faster the loss. Therefore, molybdenum electrode application parameters in the glass furnace are as following: the current density 1.0-0.7A / cm2, temperature lower than 2000℃. Further, the high iron content of the glass or "E" glass species has small consumption on molybdenum electrode.

Molybdenum Electrode and Glass Furnace

Molybdenum Electrodes is an important factor affected glass furnaces service life. Firstly, electrode installment method, such as the top electrode has not brick, so it is possible to improve the life of the furnace. But the electrode is easy to form hot-top and tends to break down. Vertical-insert electrode has smaller erosion, but higher requirement on the design and equipment. To tile electrode block, if not taking protection way, will increase the erosion of the furnace, so there has higher requirements.

The second is the correct use of a molybdenum electrode water jacket. Vertical-insert electrode water jacket is difficult to replace, so it often leads to severe leakage to shutdown the furnace. So we should often inspect and maintain the water jacket and demineralized water. Further impurities and the density of molybdenum electrodes have a certain effect on the furnace and glass quality. Molybdenum electrodes impurity content ratio and uniformity and high density is an important indicator of molybdenum electrodes. Molybdenum electrodes containing less impurity can produce better transparency glass. Further electrodes containing too much iron and nickel impurities can affect the life of the electrode. High and uniform density of electrode not only can improve the life of the electrode, to prevent electrode erosion, resulting in a large number of molybdenum particles fused into the glass, but can effectively improve the performance of the glass. Thus obtained good performance molybdenum electrodes has great significant to obtain high-quality glass.