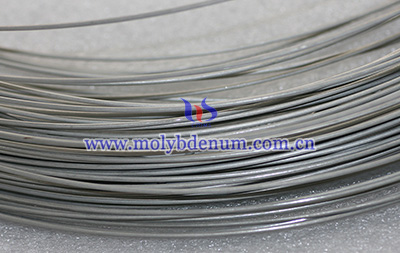

Yttrium-Doped Molybdenum Wire

Yttrium-doped molybdenum wire, commonly referred to as Y-Mo wire, is an advanced alloy wire composed of high-purity molybdenum doped with precisely 0.47%–0.60% (by weight) of yttrium (Y). The addition of yttrium introduces solid solution strengthening and dispersion of second-phase particles, which significantly enhances the wire's high-temperature stability and mechanical performance. This material is widely used in high-temperature heating elements, vacuum electronic devices, and precision lighting components.

Typical Composition (by weight)

Molybdenum (Mo): ≥ 99.4%

Yttrium (Y): 0.47% – 0.60%

Impurities (e.g., Fe, Ni, C, O, etc.): total ≤ 0.1%

|

|

Key Properties and Advantages

1.Excellent High-Temperature Strength: The refined grain structure and stable microstructure allow superior mechanical performance under prolonged high-temperature operation, typically exceeding 1800°C.

2.Outstanding Creep Resistance: The dispersed yttrium phase significantly reduces the creep rate, making the wire suitable for structural and load-bearing applications at elevated temperatures.

3.Superior Electron Emission: Y-Mo wire exhibits low work function and stable emission characteristics, ideal for use in cathode materials and thermionic emission components.

4.Improved Oxidation Resistance: Compared to pure molybdenum, Y-Mo wire offers enhanced resistance to oxidation in vacuum or inert gas atmospheres.

5.Enhanced Fabrication Properties: Yttrium improves ductility and drawability, facilitating the production of fine-diameter wires through cold working processes.

Typical Applications

1.Cathode Material for Electron Tubes: Utilized in vacuum electronic devices, X-ray tubes, and microwave components as thermionic emitters.

2.High-Temperature Heating Elements: Applied in vacuum furnaces and crystal growth systems.

3.Lighting Industry: Used in high-strength filaments for halogen lamps and specialty lighting.

4.Aerospace and Nuclear Fields: Suitable for high-temperature shielding or structural components requiring excellent thermal performance.

If there is any inquiry of molybdenum, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.