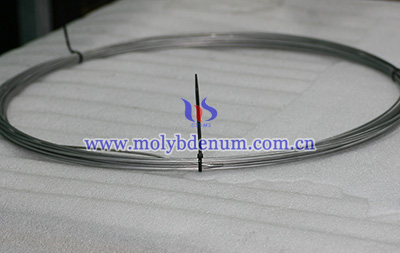

Doped Molybdenum Wire

Doped molybdenum wire is a high-performance metallic filament engineered with trace additives such as potassium (K), silicon (Si), aluminum (Al), or rare earth oxides like lanthanum (La₂O₃) and yttrium (Y₂O₃). These dopants significantly enhance the wire’s recrystallization temperature, oxidation resistance, and mechanical stability at high temperatures, making it an ideal material for demanding industrial and electronic applications.

1.Key Features

High Recrystallization Temperature: Improved grain stability prevents brittleness and deformation at elevated temperatures.

Excellent Creep Resistance: Maintains structural integrity under long-term thermal stress.

Low Vapor Pressure: Suitable for high-vacuum and clean-room environments.

Superior Ductility and Drawability: Supports ultra-fine diameters and complex forming.

Stable Electrical Performance: Ensures consistent current-carrying capability and arc initiation.

|

|

2.Main Applications

Vacuum Coating Industry

Used as evaporation sources and filament supports in PVD processes for optical, semiconductor, and decorative coatings.

Lighting Industry

Applied as filament supports and frame wires in halogen lamps, HID lamps, and other high-intensity discharge light sources.

Electronics & Power Devices

Used as cathode support structures in vacuum electron devices and high-voltage rectifiers.

Semiconductor and Solar

Employed in precision fixtures and electrodes during wafer processing and solar cell metallization.

3.Available Grades

Si-Al-K Doped Mo Wire: Ideal for PVD and lamp filament support.

Rhenium Doped Mo Wire: Enhanced anti-recrystallization and electron emission performance.

Lanthanum Doped Mo Wire: Exceptional creep resistance for high-load heating components.

4.Specifications

Purity: ≥99.95% Mo (excluding dopants)

Dopant Content: Typically 0.1%–2% depending on wire type

Diameter Range: 0.025 mm – 3. mm (customizable)

Form: Coil, spool, straightened, or cut-to-length

Surface: Cleaned, black, or bright finish

If there is any inquiry of molybdenum, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.