Molybdenum Wire for Vacuum Coating

Molybdenum wire for vacuum coating is a high-purity metallic wire specifically developed for use in vacuum deposition technologies, such as thermal evaporation and electron beam evaporation. Thanks to its excellent thermal stability, electrical conductivity, and resistance to chemical reactions under high-vacuum conditions, it plays a critical role as a heating or supporting element in various thin-film deposition processes.

Key Characteristics

1.High Melting Point: Molybdenum has a melting point of approximately 2620°C, making the wire suitable for high-temperature vacuum environments.

2.Excellent Thermal and Electrical Conductivity: Ensures efficient heating and stable performance during evaporation or sputtering.

3.Low Vapor Pressure: Maintains material integrity under high vacuum without contaminating the coating environment.

4.Good Mechanical Strength: Resists deformation and breakage under thermal stress, ensuring longevity and consistency in performance.

5.High Purity: Typically >99.95%, minimizing impurities that could affect film quality or process stability.

|

|

Applications

1.Thermal Evaporation: Used as a filament or coil to heat and evaporate coating materials such as aluminum, chromium, or gold in vacuum chambers.

2.Electron Beam Evaporation: Employed in support structures or boats due to its ability to withstand focused high-energy beams without significant degradation.

3.Sputtering and PVD Processes: Occasionally used as a structural or conductive component in physical vapor deposition setups.

4.Thin-Film Electronics and Optics: Widely used in the production of semiconductors, optical lenses, displays, and solar panels where precise coating is essential.

Product Forms and Specifications

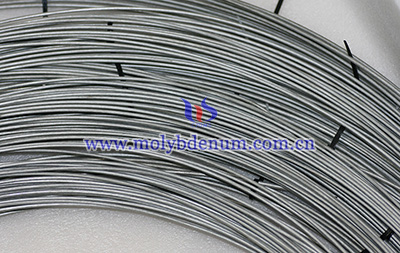

Diameter Range: Commonly available from 0.05 mm to 1.0 mm or customized upon request.

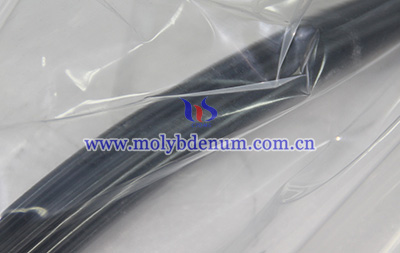

Surface Finish: Can be supplied in black, cleaned, or bright (chemically polished) finish to suit specific process requirements.

Spool Packaging: Wires are typically delivered on spools to ensure easy integration with coating equipment.

Advantages in Vacuum Coating

1.Maintains structural integrity over long deposition cycles.

2.Minimal outgassing, ensuring cleaner coating chambers.

3.Cost-effective alternative to platinum or tungsten in many applications.

If there is any inquiry of molybdenum, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.