Molybdenum Hammer for Crystal Growth Furnace

Monocrystalline silicon has a basically complete lattice structure and is an important part of crystal materials. It is mainly used to make semiconductor components, diodes, heavy-duty rectifier, high power transistors, and switching devices. The follow-up products, integrated circuits and semiconductor separation devices, have been widely used in various fields and also play an important role in military electronic equipment.

Silicon single crystal furnace is an important crystal growth equipment in the single crystal silicon industry chain. The main growth methods of single crystal silicon are the float zone (FZ) and the Czochralski. The Czochralski method has the advantages of large single crystal quality, large diameter, low cost and high production efficiency, and is favored by many single crystal silicon producers.

The Czochralski method is to melt a cooled seed crystal in contact with a silicon melt. When the temperature of the interface is lower than the freezing point, the seed crystal starts to grow. In order to make the seed crystal grow continuously, it is necessary to gradually reduce the temperature of the melt and rotate the seed crystal chuck device to improve the temperature distribution of the melt. When the crystal grows to a certain stage, the seed crystal chuck device must be lifted slowly to expand the heat dissipation surface. Therefore, the reliability and stability of the seed chuck device in the Czochralski silicon single crystal furnace are very important.

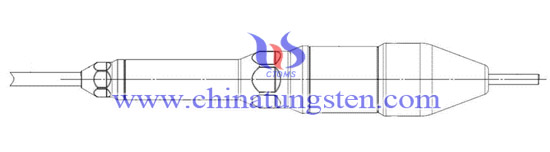

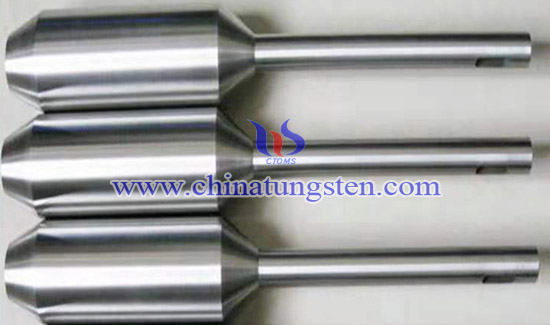

Molybdenum hammers are mainly used to connect molybdenum seed chuck and tungsten wire rope, and plays a stable and vertical role in the process of pulling the crystal by the seed crystal chuck. Generally, they weigh 7 to 18 kg. The thermal field of crystal growth furnace requires that the materials used have the characteristics of high temperature resistance, low pollution, high temperature creep resistance, etc. Therefore, tungsten and molybdenum are widely used materials for various components of the thermal field, such as tungsten crucible, molybdenum crucible, tungsten rod heating element, molybdenum heat shield, molybdenum guide tube, boat and so on.

As a material for thermal field, the molybdenum content in the molybdenum hammer is not less than 99.95%, the concentricity is the same as that of the molybdenum seed chuck, the size tolerance is within ±0.02mm, the thread opening is required to be smooth, and the product finish is required to be high. Products are customized according to drawings.

If there is any inquiry of molybdenum, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.