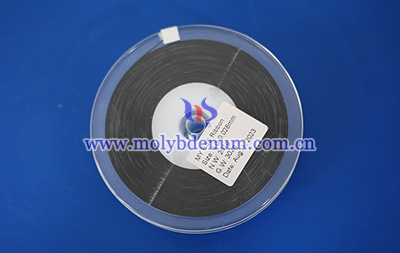

Molybdenum Ribbon for Quartz Glass Lamp

The softening temperature of transparent quartz glass is high, and it has good thermal shock resistance, making it the ideal material for high-intensity light sources. The vast majority of high-intensity gas discharge lamps use quartz glass as the material for the arc tube or bulb. However, due to the low coefficient of thermal expansion and high sealing temperature of quartz glass, it is challenging to find a high-temperature-resistant metal with a similar thermal expansion coefficient to match and seal it. Nevertheless, quartz glass can be well sealed with a molybdenum ribbon, which serves a dual purpose of sealing and conducting electricity inside the lamp tube.

Molybdenum ribbons come in pure molybdenum and rare earth molybdenum (typically molybdenum-yttrium alloy) varieties. Adding rare earth oxides to molybdenum can significantly improve the material's microstructure, increase recrystallization temperature, and enhance high-temperature performance. Since different rare earth oxides have different physicochemical properties, resulting in differences in alloy material performance, the choice of doping elements should be based on the specific requirements of the material properties and economic considerations.

Moreover, molybdenum ribbon can also be used as structural support elements inside quartz glass lamp. It helps reinforce the lamp's structure and provides stability, especially in applications where the lamp may experience mechanical stress or thermal expansion.

|

|

In general, the surface quality requirements for molybdenum ribbon include no cracks, peeling, wrinkles, distortion, oxidation, pinholes, or non-metallic inclusions. The edges should be free from sawtooth or burr defects. The molybdenum ribbon should be flat, with minor rolling imprints allowed.

The sealing between quartz glass and molybdenum ribbon is a non-matching seal. The edges of the molybdenum ribbon are blade-shaped on both sides, resulting in an elliptical seal. After sealing, as the sealing piece gradually cools, it experiences significant differences in thermal expansion coefficients with quartz glass above 1400°C. However, since quartz glass has relatively low viscosity, it still exhibits some flowability. Under slow cooling conditions, permanent stress is generally not generated. When the sealing temperature drops below the softening point, quartz glass loses its plastic deformation ability.

Since the coefficient of thermal expansion of molybdenum ribbon is greater than that of quartz glass, the shrinkage of the molybdenum ribbon is greater than that of quartz glass, resulting in tensile stress at the interface between the molybdenum ribbon and quartz glass. As molybdenum ribbon is a ductile metal and thin, it undergoes plastic deformation under the action of this tensile stress, thereby eliminating the stress caused by the different thermal expansion coefficients. This ensures that internal stress is fully released, and the quartz glass and molybdenum ribbon remain bonded together without fracturing, maintaining excellent airtightness of the seal.

If you have got any question or inquiry regarding molybdenum, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.